Dorsten's History - Station 15: Ruhrgas (Translation Lyn)

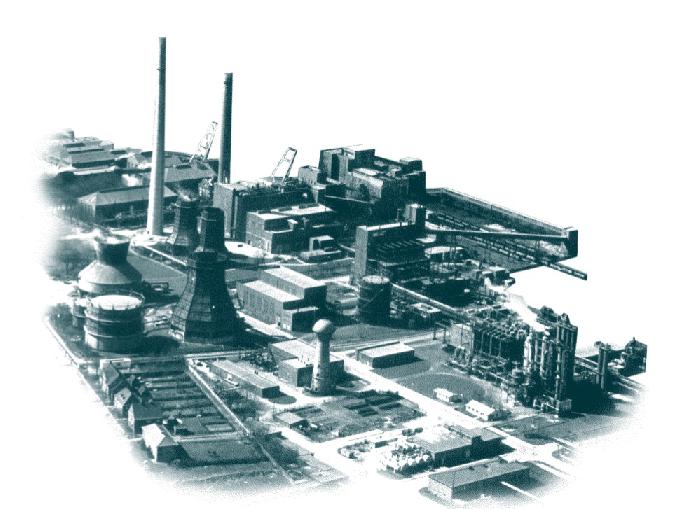

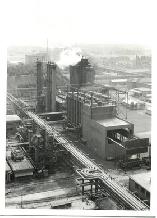

The first factory installation, producing gas from hard coal using a high pressure process, is grounded in Dorsten in co-operation with the geographically neighbouring mine-shafts of "Fürst Leopold and Baldur". The first installations can be used in the Summer of 1955, following just 18months of construction work.

Up until 1966, 4 million metric tons of hard coal from the mine-shaft "Fürst Leopold-Baldur" are purified in order to produce the exchange gas of the coking plant. The ash resulting from the gasification process (approximately 0.9 million metric tons) is a sort-after by-product for the building and stabilising of dams. The Dorstener Factory has customers from all over Europe.

Coke Production Installation |

1949 |

_ |

Initiated by Ruhrgas AG, the first attempts at coke production from local hard coal begin at the "Ruhrchemie" site in Oberhausen-Holten. The coal extracted in Dorsten achieves by far the best results. | |

|

The Ruhrgas AG board of directors decide on the foundation of the

| _ |

1953 |

_ |

The first factory installation, producing gas from hard coal using a high pressure process, is grounded in Dorsten in co-operation with the geographically neighbouring mine-shafts of "Fürst Leopold and Baldur". The first installations can be used in the Summer of 1955, following just 18months of construction work. |

Chemical Laboratory in the 1960's |

1966 |

_ |

The production of coal gas under pressure is stopped for economic reasons - the price of coal had increased by this point in time to five-fold its initial price. The "Steinkohlengas AG" is dissolved in 1967. Town gas is produced during the next two decades from the conversion of natural gas. | |

|

The Federal Republic of Germany gets gas from the Netherlands.

| _ |

1968 |

_ |

Ruhrgas erects a Research and Development Centre on the site, in order to fulfil the technical requirements for the general introduction of natural gas. |

|

The first natural gas from the Soviet Union reaches the Federal Republic of Germany

| _ |

1973 |

_ |

The "Ruhrgas-Sommers-Method" which is developed here and which enables a flexible setting of the burners in gas boilers, is used all over Europe. |

|

Norway has supplied the Federal Republic for two years wih natural gas from the North Sea.

| _ |

1979 |

_ |

As a consequence of the first oil price crisis, a test installation for high pressure coal gas (100 bar) is started to enable a natural gas exchange gas to be produced. |

|

|

1990 |

_ |

A procedure developed in Dorsten for the exact calculation of natural gas quantities starts to be used world-wide. The first condensing boilers incorporating a particularly low-emission gas burner, which was developed in Dorsten, become commercially available. | |

200kW- Fuel Cell |

1992 |

_ |

For the first time in Germany, a 200kW Fuel Cell Installation starts up its operation for the efficient production of electricity and heat. | |

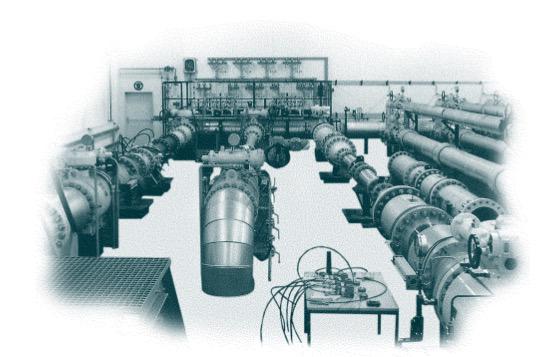

High-Pressure Testing Station |

1993 |

_ |

The high-pressure testing station "Pigsar" is used for the exact calibration of Gas Meters. It has been classified since 1999 as the "National Norm for High-Pressure-Gas" because of its high quality. | |

|

|

2001 |

_ |

A new measuring system, using miniature sensors for determining the calorific value of natural gases, is awarded a prize for innovation by the "Fachverband Sensorik". | |

|

|

2003 |

_ |

50 Years of Ruhrgas in Dorsten |

[zurück]

Daten und Fakten

Eröffnung - 27th June 2003

Adresse - Ruhrgas, Halterner Str.

(A new location to be found)

Geodaten - 51°40'17.8 ,6°59'26.7

Zeitdokumente in Bildern

Die Ruhrgas-Anlage

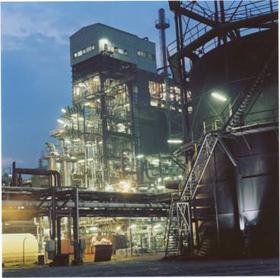

Abendstimmung - Blick auf die Anlage

Bild aus den 60ger Jahren